Heavy Copper Circuit Board

Heavy copper circuit board definition

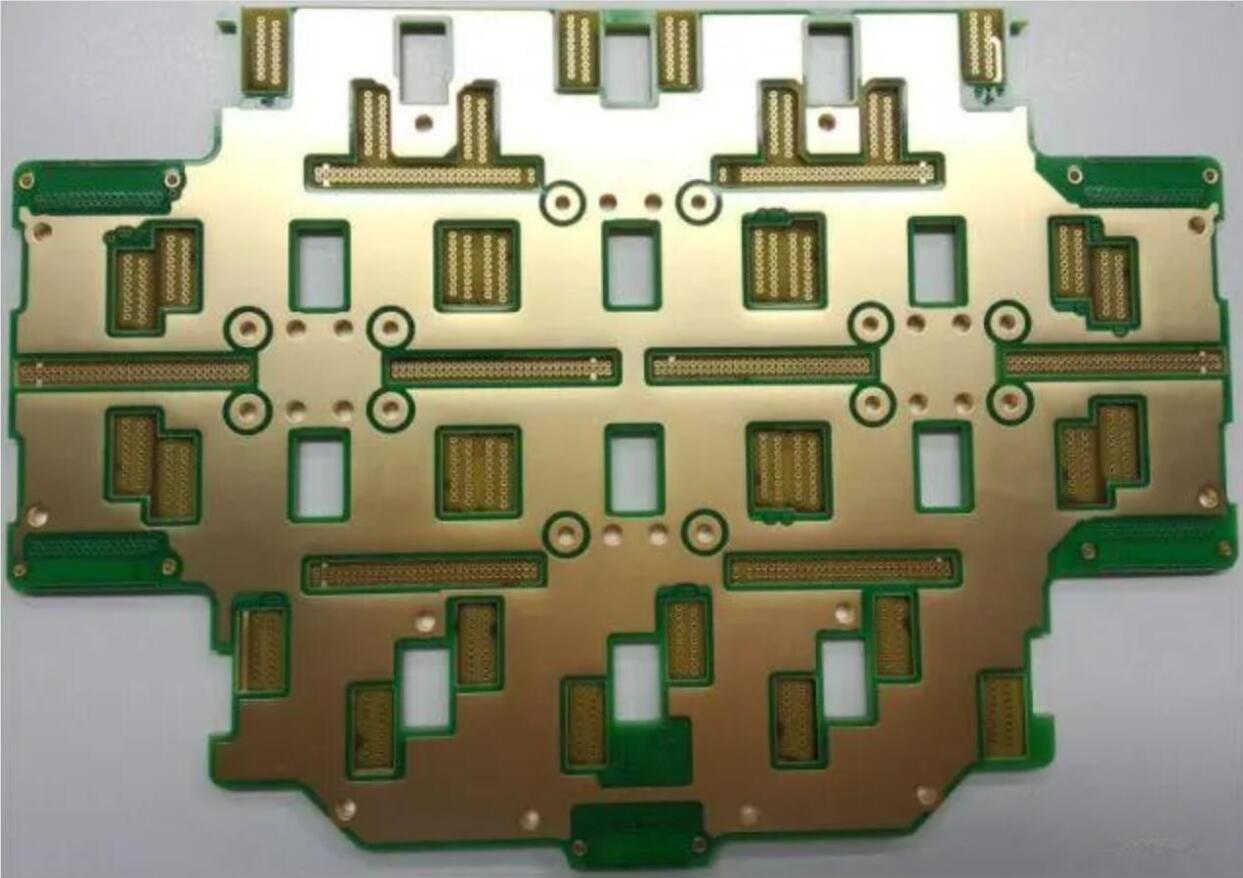

Generally, copper foil with a thickness of 105μm (per unit area 3oz/ft²) and above is collectively referred to as heavy copper foil, and copper foil with a thickness of 300μm and above is called ultra-heavy copper foil, made of heavy copper foil and ultra-heavy copper foil PCB is called "heavy copper printed circuit board". Compared with conventional printed circuit boards, the most prominent advantage of this type of heavy copper printed circuit board in terms of performance is that it can stably pass large currents and can better dissipate the heat generated by the load high current, so it is also called high-current printed circuit board.

Heavy copper printed circuit board production

Compared with the production of ordinary boards, the production process of thick copper foil printed circuit boards has many difficulties. The etching accuracy, laminated structure, drilling processing, and solder mask printing all have their own special difficulties. Currently ,there are three main methods for making heavy copper:

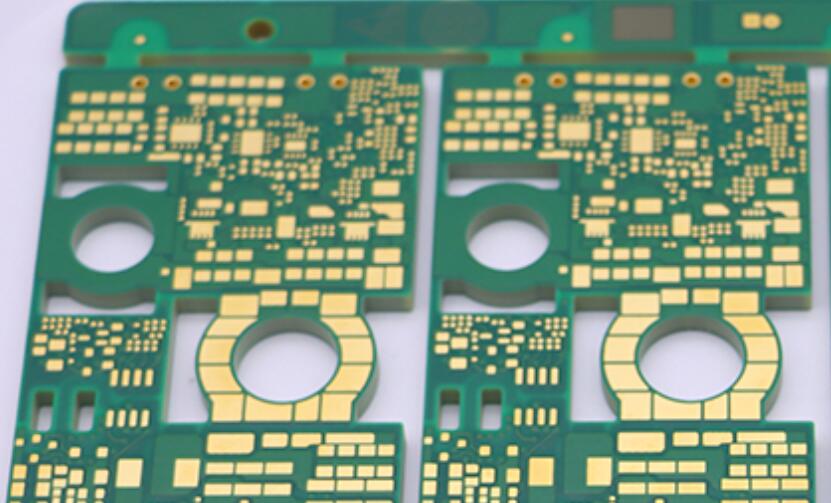

We developed some process for high power automatic application and some 12 oz board and 12+2 oz board in production now. The later one has different copper thickness on the same layer. However, this process is complicate and cost is high. Recently, follow our automotive customer’s requirement, we start to develop the “bus bar” PCB. This technology embeding thick copper bar into PCB for carrying large current. The process is not special to us for we already have lots of experience in coin embedding PCB. Since many of the high power circuits do not need to use thick copper everywhere. This design can save material cost and PCB weight. Different copper thickness foil can be put into same layer. The resin flows into the thick copper pattern space is also easy. Besides, the bus bar play a roll of heat sink. The high power component can sit on the coin surface for heat transfer.

Heavy Copper PCB Capabilities

It is important to consider the capabilities of heavy copper PCB when using them for some applications. This type of PCB is more expensive to produce based on their requirements. A heavy copper PCB should have these capabilities;

A minimum board size of 6mm by 6mm and a maximum board size of 457mm by 610mm

Copper thickness is greater than 3oz for each square foot.

A board thickness between 0.6mm and 6mm

Maximum external layer copper weight should be 18oz

Solder mask color should be either green, blue, red, black, white, purple, or yellow

Silkscreen color is white, yellow, or black

The surface finishing should be Immersion Gold, OSP, and HASL LF

The finished thickness is between 0.020 inches and 0.275 inches

Heavy Copper PCB manufacturing demands proper care, and inappropriate handling during manufacturing process can lead to poor performance, always consider services of an experienced manufacturer.

high current pcb

Hitechpcb offers executive PCB manufacturing facilities for various types of PCBs. Hitechpcb has specialized in Heavy Copper PCB manufacturing over the last 15 years and developed an image for high-quality production.

If you are looking for a Heavy Copper PCB manufacturer, Hitech Circuits offers complete solutions that you need for your PCB development.

Applications of Heavy Copper PCB

Heavy copper PCB offers some outstanding features that make it ideal for certain applications. This type of PCB is used in medical applications. The demand for heavy copper PCBs has been increasing over the years. This is because these PCBs are used in several applications such as;

Rail traction systems

UPS systems

Solar power converters

Nuclear power industries

Automotive industries

Torque controls

Power line motors

Welding equipment

Safety and signal systems

Protection relays

Conclusion

Heavy copper PCBs are produced via etching and plating methods. The major aim in the production of this PCB is to add copper thickness through sidewalls and plated-through holes. Heavy copper PCBs have several benefits which make them in high demand.

Due to their outstanding features and benefits, they can meet your electrical requirements. These circuit boards will always dissipate heat generated due to heavy currents conduction. Electronics using heavy copper boards have been in use for a long time. Heavy copper can carry high currents. These boards will continue to meet the needs of various applications.

High power circuit wirings can be developed using Heavy Copper PCBs. Such a wiring mechanism offers more reliable thermal stress handling and offers fine finishing while incorporating multiple channels on a single layer of a compact board.

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese