Plastic Molding

What is Plastic Molding?

It is important that you understand what exactly plastic molding is, and how it can benefit your business, plastic molding is the process of using a plastic molding machine and plastic mold to create plastic products.

Essentially, the plastics material goes into the heating barrel, the heating barrel has a temperature up to 280-320 degrees to melt the plastic material into a liquid, which then mixes and is forced into a mould cavity. Then cooling the mold and get the plastic sharp what you want, It is used for some of the small or big components which you want have in your ending products,

Plastic molding parts could be a part of your new model, if you are doing new product development, then you will need plastic molded parts in your whole business.

If you need specific parts for your business, first you need to find a plastic mold maker and plastic molding company. And we are the one that could solve your issue on plastic molds & molded parts.

There are several types of plastic molding processes as below, to understand this maybe help you to develop your project and find the best process to make the best result.

Plastic injection molding is a technique used to shape plastic in the form of the object you’re aiming to produce. During the injection molding process, thermoplastic polymers are injected into a mold cavity. To do this, pellets of a material are heated so they can be injected into the cavity in a liquid state. This hot liquid is then left to cool in the mold so the part can properly set. Once one part is ejected from the mold, another cycle can promptly begin.

Although injection molding can also be used for metals and glass, it’s a particularly popular production process for manufacturing plastic parts.

The steps in an injection molding process cycle include clamping, injection, cooling and ejection.

During clamping, the injection mold is prepared for a cycle by tightly clamping the two halves that form the mold cavity into place. This ensures that the molded part will have a smooth appearance and ideally the molded part should have almost no line where the different halves came together, as this shows that the mold might not be clamping tightly enough.

Once the mold halves are clamped together, the mold is ready to form a part. Before the polymer is injected into the mold, the pellets are heated to form a liquid. The liquid polymer is then injected into the mold through a nozzle. This is the injection stage of molding process, which is the second stage in a four stage cycle.

Next, the part is left to cool in the mold for a predetermined amount of time. The cooling stage can take anywhere from a few seconds to a few minutes depending on the polymer being used to produce a part. While some polymers need hardly any time to cool at all, others can take a few minutes. It all depends on the part being produced.

Once a part has cooled, the injection mold is opened and the part is ejected from the mold. The mold will clamp again and prepare for its next cycle.

Because manufacturers know how long the cycle on their molds are, they can accurately predict the amount of parts a mold will produce every hour. This helps manufacturers know exactly how many parts they’ll be able to produce every day, week and month with a fully functional mold.

Our Plastic Molding partners have various industries plastic molded parts and assemblies. Have over 20 years of extensive experience in plastic molding in a variety of materials. Customers come to us with their plastic injection molding needs because of our expertise in providing a quality, cost-effective solution to their needs. We mold in virtually all materials and can provide value-added services such as subassemblies to molded parts.

Our partners focus on custom manufacturing service for plastic molding, with the advantages of quality, stability and cost-effective. Our mainly service includes injection molding, rotational molding, blow molding, vacuum forming and plastic fabrication, and we can provide a wide variety of materials as your request, like ABS, PP, PPA, PA6, TPE, TPU, PS, TPR, LDPE, HDPE, PETG, PTFE, PA66, PVC, POM, PET, PC, PS, PE, Rubber and etc. If your products cannot be made in our factories, we will use our partner factories to produce them. And we will choose the most appropriate factory for your products and will take care of the entire production progress for you. We have a good relationship with a lot of factories which have different capabilities and we have been working together with them for a long time, so they will treat our orders as priority.

Why Choose Plastic Molding from

1. Low labor cost is one of the several main advantages of choosing

2. Complete set of production chain. From the very initial product development, to the mold design, mold production, and to the raw material purchase, serial production, product packaging, to the final stage of storage and logistics, as well as the other mechanical assembled components supply, all of these can be accomplished within an area of 10 kilometers radius.

3. Made in

4. We can save you lots of the implicit costs. Sometimes, the clients only just have an idea of what they want, they would only show us some photos or some uncompleted sketches. In this case scenario, it will require us to put client’s thoughts into practical plans and professional designs. This process will cost a lot both in the design procedures and the communications. However, we will only charge the clients the break-even mold cost, all of this effort is simply to improve the relationship with our clients and build the trust in each other. This is the foundation of our future cooperation.

5. English language is commonly used in

Plastic Injection Molding Products

1. Products:

Injection Molding, Rotational Molding, Blow Molding, Vacuum Forming & Thermoforming, Compression Molding, Plastic Fabrication

2. Services:

Products Design, Mold Making in House, Manufacturing, Surface Treatment, Assembly, Packaging and Delivery

(1) Surface Effect: Mirror Polished, Brushed Polishing, Glossy, Matte

(2) Coating: Vacuum Coating, Spray Paint

(3) Printing: Screen Printing, Silk Printing, Pad Printing, Label/Logo Printing, Hot Stamping/Decal, Laser Carving, Laser Engraving, Bronzing Printing

3. Assembly:

Stud, Inserts, O-ring, Gasket

4. Packaging

Plastic Sealed Bag, Thermoform Packaging, Carton Box, Wooden Box, Tray

5. Testing Report, QC Report

Plastic Molding supplier from China

Whether your project needs are for a few hundred of parts in a short period or millions of parts over a long period, we’ll have the right custom injection mold & molding solution to save the cost for you

To work with our plastic mold company, we do not just stop at taking your order and offer you moulds and molding parts, we work together at every step all the way, in the design and function testing until the end of the project, we will review all of the possible potential issues and bring all of the suggestion to you.

After the first sample parts coming out, our expert team will send you samples and review the parts, and we will re-sample for you from time to time until you have the perfect goods in surface, function, assembly, etc. until completely achieve your goal, your will find out we are the best plastic mold company that to support your business.

Our experienced partner team of designers and engineers has been working in the plastic mold industry for over so many years, providing innovative solutions to our clients around the world. With the advanced technology and state-of-the-art equipment, we are able to produce molds that are precise, durable, and cost-effective.

At our plastic mold company, we are committed to providing our clients with exceptional service from start to finish. We understand that every project is unique, which is why we take the time to listen to our clients’ needs and work closely with them throughout the design and production process.

We are not only plastic mold company but also offer a complete range of services, from product design and prototype to custom plastic mold manufacturing, massive production, PCB soldering, certificate, assembly, packing, and delivery, all in one convenient location, see more detail as below:

Product Design:

We offer professional product design services to help you create your own unique product. Our experienced team of designers and engineers will work closely with you to ensure that your design is not only functional but also meets your specific requirements. Our goal is to help you turn your ideas into reality.

Prototype:

We provide high-quality prototype services to help you test and validate your design. Our skilled technicians will use state-of-the-art equipment to create a prototype that meets your exact specifications. if have any issue we will improve the design and re-prototyping again until everything is perfect. This ensures that you can visualize and test your product before committing to mass production.

Custom Plastic Mold Manufacturing:

Once the design is completely finished, next step is mold manufacturing, our custom plastic mold manufacturing service allows you to achieve your specific requirements with precision and quality. We use only the finest materials and the latest technology to provide fast and accurate mold production services that meet your requirements.

Mass Production:

Our massive production services ensure that your product is produced with the highest level of precision and quality. We use the latest technology and equipment to ensure that your products are manufactured efficiently and with consistent quality.

PCB Soldering:

Our PCB soldering services provide you with a complete solution for your electronic product needs. Our team of skilled technicians can assemble and solder your PCB boards with the highest level of precision and quality.

Certificate:

If we do completely product for you, we believe your product needs some certificate, this is only way to make sure your product is safety and long last. We understand the importance of product safety and quality. That’s why we provide a comprehensive certification service to ensure that your product meets all necessary safety and quality standards.

Assembly:

Our assembly services provide you with a complete solution for your product needs. Our team of skilled technicians can assemble your products with the highest level of precision and quality by 100% inspection before delivery.

Packing and Delivery:

Our packing and delivery services ensure that your products are shipped safely and on time. We use only the finest materials to ensure that your products arrive in perfect condition.

We are committed to providing exceptional service that goes above and beyond your expectations. Our plastic mold company has served clients in various industries, from small startups to multinational corporations. We have a proven track record of delivering high-quality products and services that meet our clients’ needs, on time and on budget.

Our experienced team of designers, engineers, and technicians work closely with you to ensure that your project is a success. We use only the finest materials and the latest technology to provide fast and accurate mold production and assembly services that meet your requirements.

In addition to our services, we also offer exceptional customer service. Our team is always available to answer your questions and address your concerns. We believe that communication is key to a successful project and strive to keep you informed every step of the way.

Thank you for considering Sincere Tech for your product design, prototype, custom plastic mold manufacturing, massive production, PCB soldering, certificate, assembly, packing, and delivery needs. We are dedicated to providing you with the best possible service and solutions to help you succeed. If you have any questions or would like to learn more about our services, please contact us at sales@hitechpcb.com

Plastic molding company

Our Plastic molding company has injection machines from 60T – 2000T to support various customers

As you can tell from our website that we are a professional plastic mold company, our goal is to help your business, to success your project with our best solutions on your project, so that you can make the most advisable decisions about which supplier is the best partner for your business.

below we have a more valuable suggestion for you to make a decision based on your production and quality needs. The more you know, the better your choices will be. If you want to know more suggestions from our team, please contact our technical team, we will offer you the best solutions to reduce the cost to your project and make your project going fast, smoothly and successfully.

Are you ready to start your new project now? Contact our team and let us be your partner all the way together, you will be 100% happy with sincere tech plastic mold company.

How important of injection molding materials

Injection molding materials play a critical role in the injection molding process as they determine the properties and quality of the final product. The following are the reasons why injection molding materials are important for the injection molding process:

1. Product Properties: The material used in injection molding affects the final product’s physical and mechanical properties such as strength, stiffness, flexibility, hardness, toughness, and heat resistance.

2. Processing: The material must have appropriate flow characteristics to ensure proper filling of the mold cavity, as well as good dimensional stability during cooling.

3. Cost: The material cost is a significant factor in determining the overall cost of the injection molding process. Some materials are more expensive than others, and choosing the right material can help to optimize the cost-effectiveness of the process.

4. Availability: The availability of the material can impact the lead time for producing the parts, so it’s important to choose a material that is readily available to minimize production delays.

5. Quality and Consistency: The quality and consistency of the material can have a significant impact on the quality and consistency of the final product. A consistent material can help to ensure consistent part quality, which is important for many applications.

Therefore, the selection of the appropriate material is crucial for the success of the injection molding process, and it is important to carefully consider all the factors involved in choosing the right material for the job.

Our partner provides hundreds of injection molding materials solutions, with a few proprietary materials engineered right within their facilities. Many material offerings are tied in with a specific technology due to the nature of the manufacturing processes.

Below, the materials (which are often indicated by the technology they are married to) have been categorized into model/ prototype parts and functioning durable parts capable of meeting production requirements. It is best to consult with our Project Engineers if your material requires regimented standards and for further specifications.

Fine Feature Detail

1. PolyJet Standard & PolyJet HD

2. PolyJet Flex & PolyJet OverMolding

3. Stereolithography (SLA) & High Definition Stereolithography (HDSL)

4. ID-Light™

High Temperature

1. Selective Laser Sintering – PEEK and FR 106 materials

2. Fused Deposition Modeling – ULTEM

3. CNC Machining

Functional & Durable

1. Thermoplastics, Urethanes, Nylon & Nylon Composites, Metals

2. Selective Laser Sintering (SLS) – Nylon 12 and Nylon 11 Materials

3. Fused Deposition Modeling (FDM) – ABS and PC-ABS thermoplastics

4. Additive Metal Manufacturing (AMM), Direct Metal Laser Sintering (DMLS) – Stainless Steel, Inconel, Cobalt Chrome

5. CNC Machining

6. QuantumCast™ Advanced Cast Urethanes

Production

1. Selective Laser Sintering – PEEK and NyTek

2. Additive Metal Manufacturing (AMM), Direct Metal Laser Sintering (DMLS)

3. Fused Deposition Modeling – PC-ABS, ULTEM

4. QuantumCast Advanced Cast Urethanes

5. Composites

6. plastic mold manufacturing and Injection Molding

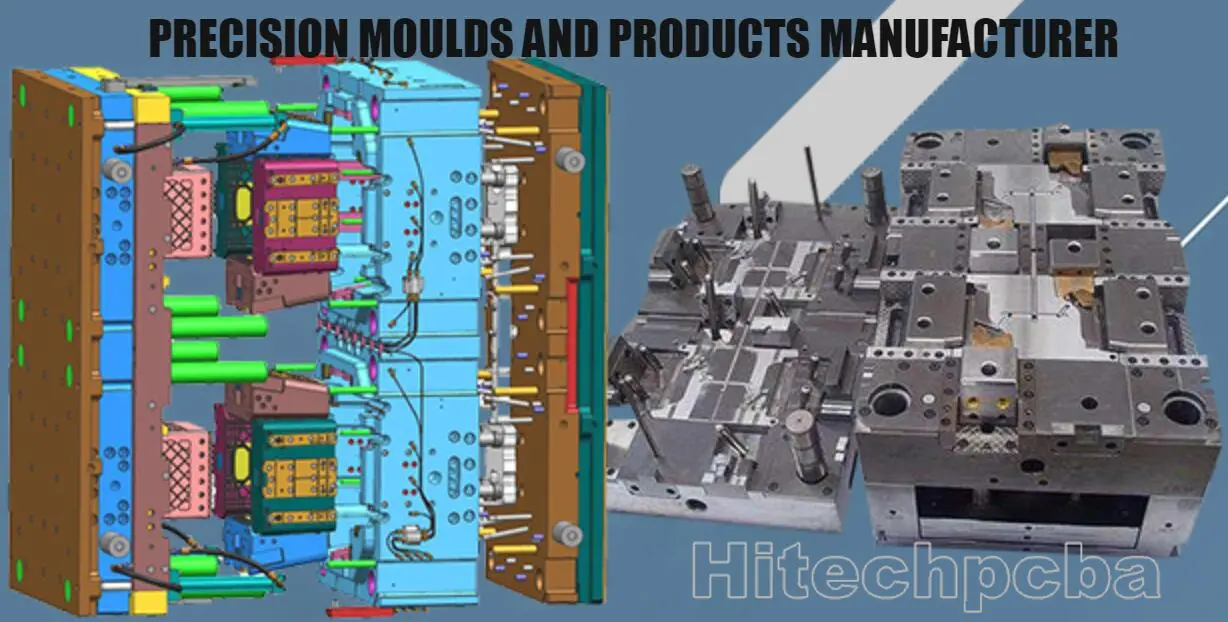

MOLD DESIGN CAPACITY

Professional mold design engineers with more than ten years experiences

We have Tooling designers with more than ten year experiences

Project managers with fluent English skill and rich experience more than 15 years

Top skilled Tooling manufacturing staff and professional shipping staff

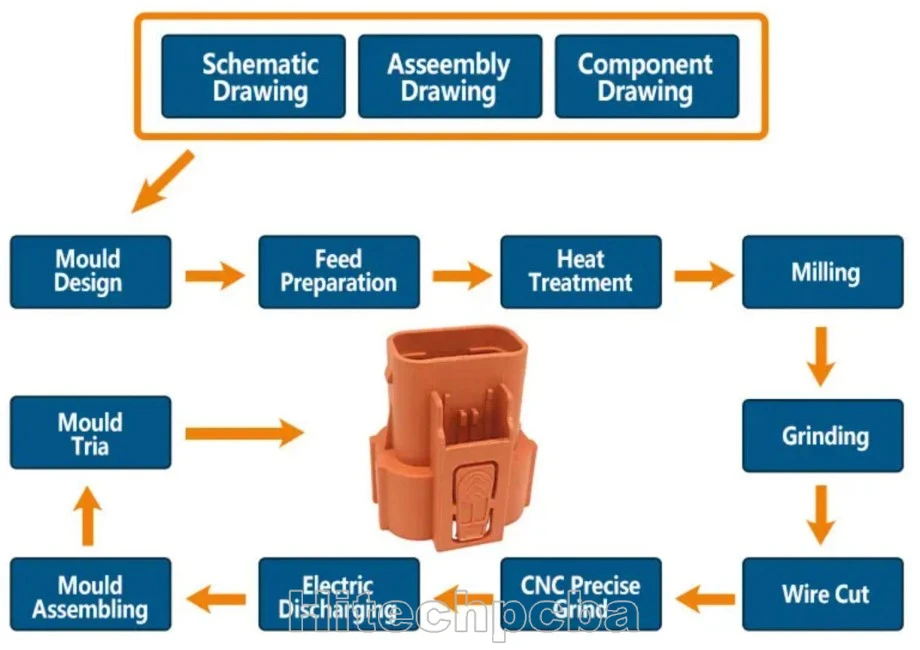

Procedure for tooling design,

DFM Report and Mold Flow First(Choose the best gate point)

DFM approved-3D Mold Design with whole assembling components in it. also 2D assembling layout with BOM list

We not only satisfy your demands as your supplier but also we energetically look for methods to optimize your mould structure therefore save your cost and time during long period massive producing. We have good quality management techniques that are so successful.

Tooling drawing approved-Mold flow with cooling line, production drawing.

We analyze, improve and completely finish any existing mould issue may have that is not reaching your demands and specifications. As the best mold manufacturer in

There are automatically profits along when you work with our organization of our dedication, our high grade steel materials & manufacturing tolerance standards, our highly effective system approach to each of the processing, from designing up to shipping.

Injection mold design is one of the most challenging yet interesting jobs in the field of plastics. This is great for people who want to use their creative abilities. That is one of the main requirements needed to make new projects and new designs.

Some may think this job is easy due to the use of CAD programs. These courses will help a person learn about the job and programs to help them along the way. These projects are just tools to assist the designer. The designer has to come up with new methods for making plastic molds. This is going to require inventiveness. Some may wonder what a plastic mold designer does in a typical day at work. Many have a schedule similar to mold makers. They work closely together since the makers are manufacturing their designs.

The designer consults with the mold makers, CNC programmers and WEDM programmers. This way they can work on a design that is realistic and functional. The designer usually works a shorter day then the mold makers. They have to put the design together but they do not have to construct the mold or the plastic. They may help out in the shop sometimes. This is common during slower seasons This will also allow them to get in some more hours and see their designs come to life. To many this will sound like an interesting career choice. Wondering how to become an injection mold designer? There are two career paths in the

Many designers have a background in mold making. Plastic Mold makers learn about designs on the job or they go to school for it. Some companies may also pay for the additional training. Previous experience in the field will help them use realistic approaches to their design. Technology based schools and universities offer programs that focus in plastic injection mold design. A background in mechanical and mathematics is beneficial. This will help with the design process. The plastic field is growing and skilled designers are in demand but the supply is low.

The mold design field is competitive at the global level. The designer and Plastic mold maker can live in different parts of the world. The project manager will have to spend a lot of time on the phone and email to ensure proper communication. Working in the injection mold design field has its challenges but is interesting. There is job security and the field pays well. There are good courses to learn the skills to become a designer.

LOOKING FOR PLASTIC MOLDING SERVICES?

If you have a new project that needs plastic molding services, but not sure if the part structure is resonable to make plastic mold or not. Then, you are welcome to consult on our technical team, we will suggest you the best solution to assist you with better design, low cost for plastic mold making, plastic molding manufacturing. Use the min invert cost to win the max return of your business.

If you want to have an estimated price for initial market evaluation, you are welcome to send us your 3D data (STP or IGS format), you don’t have any lost but have our competitive price for a reference.

We never share your data with any other third parties, we are willing to sign the Non-Disclosure Agreement (NDA) document to protect your project.

We could save you up to 40% Initial mold investment cost, if we produce the plastic molded parts for you we will never earn any piny of profits in mould making or even put 30% of tooling costing for your project (depending on the requirement of volume on your project).

If you have a technical question, you are welcome to contact our technical manager by email sales@hitechpcb.com, who speaks fluent English and has over 15-year technical working experience, will help to solve any of your technical issues and save cost for you

If you work with us. You will be impressed and fully satisfied with our quality, price, service, and fast lead time.

OUR ADVANTAGES FOR PLASTIC MOLDING MANUFACTURING SERVICES

We all know quality is the key point to keep our customers staying with us, before production we will measure all of part dimension (by CMM measurement machine) and send the report to our customer for approval, to make sure all of the dimensions are 100% completed correct, during the molding production the product quality is most effectively controlled at the machine.

Hitechpcba utilizes a fully integrated quality control procedures to verify every step before next manufacturing process, Our QC department will record every batch production to make each production traceability.

If you are looking for Plastiv molding in

PRODUCT ASSEMBLY SERVICES IN

We offer contract product assembly services, mold manufacturing, ODM, OEM manufacturing, assembly metal parts, plastic parts, PC board, electronic components assembly, soldering, and other volume added services. If you are looking for contract product assembly service companies in

In the

Base on our government export trading report

It is important for many businesses to produce their plastic and metal parts in

There are numerous pros for businesses partnering with Chinese product assembly services. As mentioned earlier, some of the important benefits are the low-cost labor rate & good quality control plus easy handy for auxiliary accessories requirement. In some cases, the costs of shipping and labor are almost equivalent to that of domestic work, but in general, this process is cheaper in

A lower-cost in the production of OEM parts in

I believe you can not able to find any others can do this job on the world, that is why iPhone stay in

As well as the pros for partnering with Chinese product assembly service, there are also some cons to this. One of the cons that American businesses run into is trouble finding a Good & responsible Chinese product assembly service Manufacturer to partner with, to find one is easy but mostly you may not able to find a good and professional Chinese contract assembly Manufacturer.

It does not seem easy for business, although there are some tactics to succeed in finding one. Another barrier that stands between American and Chinese businesses and factories is the difference in languages, thus making communication a challenge. Communication is not only difficult in communication, but also from a cultural perspective. Unlike the usual American, Chinese are exact and take everything you say literally. It is important to ensure that the Chinese understand all you say so that misunderstanding is avoided as much as possible.

If you are looking for plastic injection molding parts, product development and manufacturing, contract manufacturer or OEM product assembly services in

We Offering to manufacture products with high-quality production. We can produce any custom plastic products, metal parts, aluminum die casting, secondary process manufacturing, custom package, product assembly, and shipment services, our service range including products for construction, health/medical, vehicles, cosmetics, food, digital, appliances, as well as other fields to comply with your requests. We are able to produce our items in high quantity with the help of our professional team. We will deliver to you at an affordable price with high quality.

What services we can offer you?

To make sure that we are a good partner for you we would like to explain our advantages and our specialty, this will make sure you will find the right OEM manufacturer Partner, to satisfy you is our goal.

We can do model and part Design (inhouse work) for you, PCB board & electronic design if necessary (outsource), if you have your own PCB board supplier, you can arrange to send us. We do a prototype, CNC machining, 3D printing (inhouse) service, Injection Mold/Metal Tooling/Aluminum die casting and Mold design (inhouse work), Injection Mold, tooling or die manufacturing (inhouse work), Massive production (inhouse work), Secondary process like Painting, Chrome powder coating, anodizing (some of them inhouse work), products Assembly service and packing (inhouse), shipment to your storage house.

Above is our service which we are professional and we keep doing this service for many years. If your project requirement above services then you come to the right place.

Why you should choose us to partner with?

I believe this is the most important factor to let you make your choice, About our advantages which explained on our home page, here I would like to add some supplements to let you know a little bit more.

As we know to work with a China OEM contract manufacturer, better communication is most important, fluent English plus professional technical communication is the key point to guide the project successful and fast, on the other hand, unprofessional communication will make the project delayed and may fail the whole project.

When we receive a project from our customers, we will review all of the possible issues and bring the solution with illustration (Design for manufacture analysis), this will be easy and accurate, reduce any possible mistake or misunderstanding, we are professional and we know there is lots of mistake and misunderstanding in the communication, that is our jobs to protect this issue.

The other pros are most of the jobs are done by inhouse as we explained above, we could easy to control the time plan (especially for some urgent case, we make molds by 2 weeks fast) and the quality, we can do large order quantity or small quantity, in China to gather the employees is very easy and fast, even the new employee that can be training very quick and obedience management, this is because the Chinese culture.

When you work with us, we are with you every step on the way, in the design and development phase, we will review all of part design issue, mold manufacturing issue, product assembly issue, potential function issue, or any problem and bring all of the issues together and report to you with illustration and solutions.

After the first model sample send you, we will double check your requirement again to find any possible issue and provide the solutions, in all of this steps are checking – improving – testing until you completely satisfy the goods, this is what we do to all of our customers, hope you will be happy as well,

Want to know more about our product assembly service? You are welcome to contact us.

0086-755-29970700

sales@hitechpcb.com; sales@hitechcircuits.com

2F, Building C, Suojia Technology Park, Hangcheng, Bao’an, Shenzhen, Guangdong, China 518126

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese