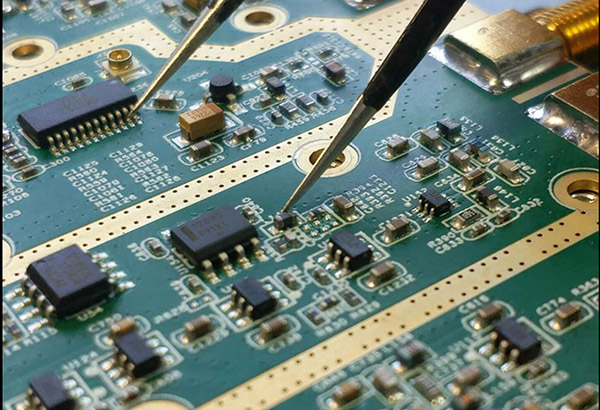

Turnkey PCB Assembly Manufacturer

What’s mean for Turnkey PCB Assembly?

Turnkey means a product or service that is ready for immediate use for the buyer and when applied to PCB assembly, this refer to the SMT factory will handle all steps for PCB assembly. Turnkey PCB assembly is including the entire steps complex in making a PCB, beginning from the fabrication process all the time to the assembly process.

In PCB manufacturing, turnkey PCB assembly also means the electronic manufacturing service, since it takes hands of the entire process of designing, manufacturing, and testing the printed circuit board.

Essentially, a full turnkey solution makes you to have enough time and focus on designing PCB, and our SMT factory can handle the rest of the steps and procedures. Turnkey solutions offer an efficient and cost-effective way to assemble and test circuit boards for products. This also offers companies a way to receive printed circuit boards with the shortest lead times possible.

Turnkey PCB assembly & manufacturing is the optimal solution for engineers with urgent, high complexity projects who want to avoid project management headaches. Providing turnkey PCB assembly services means that the provider will handle all the task including components or parts procurement, manufacturing, assembly and final delivery! Hitechpcba specializes in all types of PCB assembly projects, including full turnkey PCB assembly and partial turnkey PCB assembly. With our full turnkey PCB assembly service, we can handle every aspect of PCB manufacturing. We provide fast, reliable turnkey PCB assembly because we are experts in sourcing components, assembly, testing, delivery, after-sales service and warranty support.

PCB Board Assembly Quality Control: All bare PCB boards are assembled to comply with IPC-A-610 standards. All assembling technicians and inspectors are with skilled experience. All PCB manufacturing handles by ourselves to comply with IPC Class II or III standards upon requirements. 100% electrical test on all bare Printed Circuit Boards by flying probe or fixture. 100% visual inspection after electronic PCB assembly completion. 100% functional test as per documented test procedures (optional). 100% all PCBAs cleaning. Strict electronic static discharge (ESD) control

Hitech Circuits is capable of providing full turn-key and partial turnkey PCB assembly services. For full turn-key, we take care of the entire process, including preparation of Printed Circuit Boards, procurement of electronic components, online order tracking, continuous monitoring of quality and final assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

With Hitech Circuits PCB’s Full Turnkey PCB assembly whatever Prototype or Low Volume PCB Assembly, PCB, & PCB Assembly capability, you can go from concept to product to market in just a few easy steps. Upload your BOM file and get a Full Turnkey, PCB, or PCB Assembly price for components, labor and bare boards; it’s that simple. Our team of procurement specialists scours their sources to locate the exact parts you’re looking for, at the best price available on any given day.

The Benefits of Turnkey PCB Assembly Manufacturing

The most obvious benefit of turnkey PCB assembly is that businesses don’t have to take their focus off critical processes like continual innovation to spend time figuring out the assembly side. There’s no need to expend time and energy finding the best component costs, going through a frustrating process of procurement and then needing an in-house team to assemble them skillfully. The most significant benefits of turnkey assembly include:

Shorter production time

As a fundamental form of electronic assembly, PCB assembly primarily contains three phases: PCB fabrication, components procurement and PCB assembly. Traditionally, you should quote and confirm design files with sales and engineers working for your PCB manufacturer, then components distributors and finally PCB assemblers. Such series of quotations and confirmations just need your time spent in contacting with different partners. If those partners are from different countries, you have to overcome some problems such as time zone, communication habits etc. Full-turnkey PCB assembly, however, is a highly-efficient form of electronic assembly. As soon as full-turnkey PCB assembly is determined, an overall assembly quotation and indispensible issues prohibiting smooth manufacturing will be raised so that three times of communication have been cut to one time with electronic assembly efficiency dramatically improved.

Cost effective

With a turnkey contract, there is no extra cost to deliver freight to an assembly workshop, meaning you save a significant amount of money. Turnkey services also have good working relationships with component manufacturers and can almost always get a better price for parts than small or medium businesses.

Issue Identification

A major time and money-saving advantage of turnkey PCB assembly is the ability to spot potential issues before the circuit boards make it into any products. As part of the process, you submit a netlist file to the assembler. Before assembly begins, the assembler will check to be sure specifications match the application and identify any errors that may be present. Should any errors be found, you have the opportunity to correct the design and avoid being saddled with thousands of unsuitable circuit boards.

Streamlined Management

Dealing with multiple vendors can be stressful and a time drain, especially on small businesses with fewer human resources to go around. With turnkey manufacturing solutions, you stand a far less chance of experiencing a miscommunication because you’re managing multiple channels of interaction. These potential miscommunications can happen between you and a vendor, or even between vendors, and can lead to derailment of your timeline and wasted money.

Your turnkey supplier will likely provide you with a single point of contact through which all business will be conducted, providing you with peace of mind and lightening the burden of management in the assembly of PCBs.

How to obtain a quote for your turnkey pcb electronics ?

PCB Online Quote: An Instant PCB price can be quoted base on Board information. Full turnkey assembly cost: This is an additional instant quote for the cost of labor for Turnkey PCB assembly. BOM Pricing: To get a BOM price within 24 hours, email the BOM to sales@hitechpcb.com and include all details such as quantities, reference designators, and Parts manufacturer name and part number. Most entrepreneurs and manufacturers find the old ways of manufacturing electronics and to printed circuit board assembly very intimidating because it is slow, prone to errors, and expensive. It wasn’t designed for small batch runs and prototypes, but to support enormous orders with a long lead time. Luckily, the services of Turnkey Printed Circuit Board (PCB) assembly are coming in today to meet the needs of hardware designers

Precautions during Turnkey PCBA processing

PCBA is the abbreviation of Printed Circuit Board Assembly, which is an important link in the manufacturing process of electronic equipment. In the process of PCBA processing and production, there are some precautions that need special attention to ensure product quality and production efficiency. This article will introduce the matters needing attention in the PCBA processing and production process from the perspective of PCBA processing and production process.

1. Design stage

In the process of PCBA processing and production, the design stage is very important. In the design stage, it is necessary to consider the layout of the PCB circuit board, the selection and layout of components, the direction of the circuit and the connection method, etc. The following points need to be paid attention to during the design phase:

(1) Component selection: Selecting the appropriate components is an important guarantee to ensure the quality of the circuit board. When selecting components, you need to pay attention to the brand, model, package and parameters of the components to ensure the quality and stability of the components.

(2) Design of PCB circuit board: The design of PCB circuit board needs to consider the size, layout, line direction and connection mode of components, etc. Certain layout rules need to be followed during design to avoid interference between components and ensure the stability and reliability of the circuit board.

(3) Anti-static: During the design and manufacture of PCB circuit boards, attention should be paid to prevent static electricity interference. During operation, anti-static measures such as anti-static gloves and static mats should be used to avoid damage to components.

2. Manufacturing stage

In the manufacturing stage of the PCBA processing production process, the following points need to be paid attention to:

(1) Manufacture of PCB circuit board: The manufacture of PCB circuit board needs to pay attention to ensure the smoothness and flatness of the board surface, so as to avoid the unevenness of the board surface and cause the components to be welded weakly.

(2) Mounting of components: The placement of components needs to ensure that the position and posture of the components are accurate, and avoid damage or functional failure of the circuit board due to deviations in position or posture.

(3) Soldering process: During the welding process, it is necessary to pay attention to the control of temperature and time to avoid damage to components caused by excessive welding temperature or too long time.

(4) Quality inspection: In the process of PCBA processing and production, quality inspection is required, including the welding quality of components and the connection quality of lines, etc. In the testing process, it is necessary to use professional testing instruments and equipment to ensure the quality and reliability of the product.

3. Encapsulation stage

In the packaging stage of PCBA processing and production process, the following points need to be paid attention to:

(1) Selection of packaging materials: The selection of packaging materials needs to be determined according to the performance requirements of the product and the use environment, such as high temperature resistance, heat resistance, dust resistance, etc.

(2) Temperature and time control during the packaging process: During the packaging process, it is necessary to pay attention to the control of temperature and time, so as to avoid the failure of packaging materials or the degradation of product performance due to excessive temperature or too long time.

(3) The sealing of the package: the sealing of the package is very important to the stability and reliability of the product, and it is necessary to ensure the sealing during the packaging process.

4. Testing phase

In the testing phase of the PCBA processing and production process, the following points need to be paid attention to:

(1) Selection of testing instruments and equipment: The selection of testing instruments and equipment needs to be determined according to the performance and specifications of the product to ensure the accuracy and reliability of the test results.

(2) Setting of test parameters: The setting of test parameters needs to be determined according to the performance requirements and specifications of the product to ensure the accuracy and reliability of the test results.

(3) Judgment and recording of test results: The judgment and recording of test results need to be carried out in strict accordance with product testing standards to ensure the accuracy and reliability of test results.

Briefly, in the PCBA processing and production process, we need to pay attention to the details of each link, so as to ensure the quality and reliability of the product. In the manufacturing process, it is necessary to strictly follow the design requirements and manufacturing standards, follow good manufacturing specifications and quality management systems, and finally achieve high-quality, high-efficiency PCBA processing and production.

Common machines for Turnkey SMT processing

1. SMT machine: It is used to accurately place the components on the PCB, including automatic surface mounting machines, semi-automatic surface mounting machines and manual mounting machines.

2. Hot air soldering equipment: including hot air guns and reflow soldering ovens etc., it used to solder SMT components on PCBs.

3. SMT component storage rack: used to store and organize SMT components.

4. 3D AOI inspection equipment: used to check the placement and quality of SMT components.

5. Coating equipment: including automatic coating machine and manual coating machine, etc., used to coat the glue on the surface of PCB.

6. Solder paste printing machine: used to print solder paste on PCB for use in subsequent soldering process.

7. Wave soldering equipment: used for soldering DIP components, such as connectors, sockets, etc.

8. Cutting machine: used to cut the PCB after patch into a single board.

9. Cleaning equipment: used to clean the PCB after assembly, and remove the residual glue and solder paste.

The above are some equipment commonly used in SMT assembly processing, but which equipment and tools need to be used shall be determined according to the actual situation and process requirements.

Common inspection methods for Turnkey PCB Assembly processing

Our testing and inspection equipment are suitable for simple as well as complex PCB assembly requirements. We can take on extremely demanding projects, and ensure high quality product yield.

1. Optical inspection method

With the reduction of package size for SMT components and the increase the density for PCB assembly, SMA inspection is becoming more and more difficult, and manual visual inspection is insufficient now, and its stability and reliability are difficult to meet the needs in our production and quality control, so the use of optical inspection is becoming more and more important.

2. Artificial visual inspection method

This method requires less investment and does not require the programs, but it’s slowly and required directly visual inspect the tested area. Due to the shortcomings of visual inspection, it is rarely used as the mainly quality inspection method in the SMT production line, but most of them are used for repair and rework.

3. AOI method

Using automated optical inspection as a defect reduction tool, it can be used to find and eliminate errors early in the SMT process for good quality control. AOI adopted advanced vision system, new lighting method, high magnification and complex processing method, so as to obtain high defect capture rate at high test speed.

Turnkey PCB Assembly Rework & Repair Guidelines

PCBA Boards can be reworked and repaired. However, only reasonable operations based on scientific guidelines can guarantee the quality of PCBA boards;

1. PCBA rework and repair basis

Rework and repair of PCBA must be performed in accordance with PCB design documents and repair regulations, and there also must be a unified rework and repair process.

2. The rework times allowed for each solder joint

Rework is allowed for defective solder joints, and rework for each solder joint shall not exceed three times, otherwise it will cause damage to the solder joints.

3. Use of removed components

In principle, the disassembled components should not be used anymore. If they need to be used, they must be screened and tested according to the original electrical performance and process performance of the components, and the installation is allowed only when they meet the requirements.

4. Times of desoldering on each pad

Each printed pad should be desoldered only once (that is, only one component is allowed to be replaced). The thickness of the intermetallic compound (IMC) of a qualified solder joint is 1.5~3.5μm, and the thickness will increase after remelting, even when it reaches 50µm, the solder joint becomes brittle, the solder strength decreases... As a result, there are serious reliability risks under vibration conditions.

5. Bow and twist requirements for surface mounting and mixed mounting PCBA assembly and soldering

The bow and twist of surface mounting and mixed mounting PCBA assembly and welding are less than 0.75%.

6. Total times of PCB assembly repairs

The total times of repairs for PCB assembly is limited to six; In other words, excessive repairs and modifications affect PCBA reliability.

Production requirements for Turnkey PCB Assembly processing

1. The production line is set up reasonably and all the labels are correctly posted, warehouse materials and parts should be stored in categories and stacked neatly.

2. Product batch management: The defective product control procedure should clearly stipulate the isolation, identification, recording, review and treatment for these defectives. Typically, there should be no more than three times rework for product and no more than twice for component reworks.

3. Civilized production: clean, no debris, civilized operation, no brutal and disorderly operation. On-site management must have rules and regulations, inspections, evaluations and records, and carry out "6S" activities every day.

4. The maintenance for SMT production line machine and equipment: key equipment should be regularly inspected by special staff, to keep the machine in good condition at all times, we also need to track and monitor the equipment status, and if find problems for machines, we need to take correct solutions to fix and repair it in time.

Our full turnkey PCB assembly is a highly-efficient and fast form of electronic assembly. You don’t need to worry about managing multiple vendors as we take care of the entire fabrication.

With our full turnkey PCB assembly services, you can build and refine prototypes faster, easier, and cost-effectively.

We are all equipped to handle (through-hole, surface mount, mixed) small batch of boards or full production runs.

We have verified supply chain networks to support the entire process of turnkey assembly. With end-to-end solutions from a single provider, you can gain significant cost savings, too.

We have a team of highly qualified staff who are experienced in working on turn-key circuit board assembly. They not only help meet your expectation in terms of quality, but also complete your projects faster.

Hitech Circuits offers many services to help you turn your ideas into products, including PCB assembly services. As a turnkey assembly provider, we guarantee that we’ll treat your product with care so that your customers are thrilled with the quality they receive. We understand that contracting with a turnkey provider involves a lot of trust, so we rely on a high-quality process to earn and maintain that trust. If you are looking for a partner to provide electronics assembly services for your product, we invite you to contact us for a PCB assembly quote.

0086-755-29970700

sales@hitechpcb.com; sales@hitechcircuits.com

2F, Building C, Suojia Technology Park, Hangcheng, Bao’an, Shenzhen, Guangdong, China 518126

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese