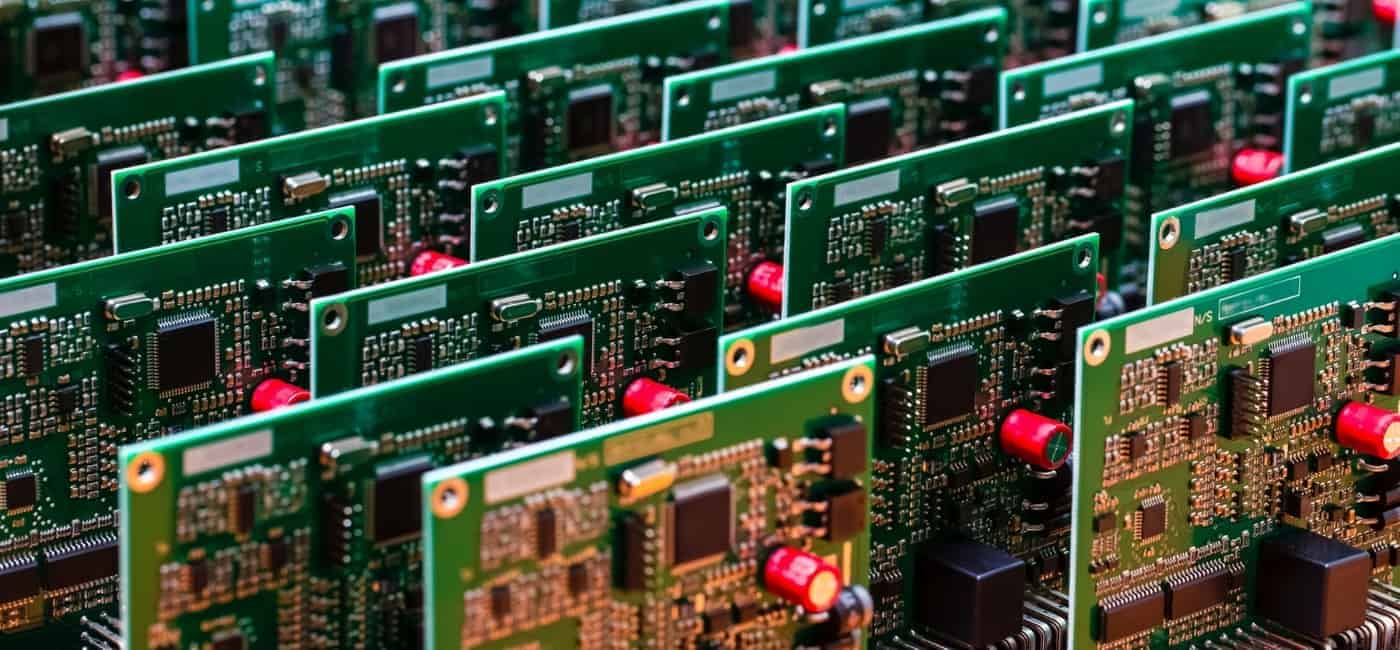

Low Volume PCB Assembly

What is Low Volume PCB Assembly?

Low Volume, Small batch, as the term implies, is a batch with limited number of assembly batches. While some OEMs manufacturing electromechanical products require PCB Assembly in bulk, a Low Volume PCB Assembly may be required for a limited edition product or one with very specific requirements. In such a scenario, it is crucial to first make a low volume prototype PCB assembly as that would give an idea about the final product and if it requires any changes.

Hitechpcba is an experienced full service electronics contract manufacturer; however, volume has never been an issue for us. We offer PCB assembly services including prototyping even for low volume orders and regardless of the complexity of the requirement.

There are many names for small batch printed circuit board (PCB) assembly. Other names you will commonly hear are: surface-mount technology (SMT) PCB prototypes, PCBA prototype assembly, PCB sample assembly, etc.

The term PCB assembly refers to a fast prototype PCBA used to test the function of new electronic designs. These help with quality assurance, verifying that there is no problem with the test product, finding bugs, and updating the design. Typically, before mass production, one electronic project will need 2-3 iterations of a SMT assembly to make sure everything is working perfect.

Hitechpcba has a strong engineer team to back up; most of them with over 10 years in the electronic manufacturing fields. If you need a small batch of boards; there are customization requirements for component packaging, component specifications, assembly techniques or density levels. You can contact Hitechpcb as a reliable OEM PCB assembly manufacturer. And we can provide the Low Volume PCB Assembly service you need at your budget.

1. Small-batch, multi-variety SMT lean production in quality control and large-scale production is not much different, just because of frequency. There are a lot of online adjustments and exception handling processes every day. In the small-batch, multi-variety production state, the operator is not only will be simple work in feeding and feeding but also skilled in parameter adjustment, machine abnormal processing and other skills. and in the high-volume production state, the main work of the operator is only for simple operations such as feeding. Starting from production and quality control. Operators with comprehensive skills, carefulness and a strong sense of responsibility should be arranged to carry out small batches and multi-variety production. The smaller the batch, the more complicated Products, the higher the dependence on the operator, so it is necessary to strengthen the training, there are a corresponding incentive and responsibility system to improve the operator’s professional skills.

2. Emphasize that quality is produced rather than tested, and process quality management is used to ensure final quality. During the production process Quality inspection and control are carried out in every process. Focus on cultivating the quality awareness of each employee to ensure timely quality problems

Hitechpcba supports engineers to assemble their electronic prototype quickly and cost effectively during the whole design verification process. To ensure that the product design meets requirements, in general, we suggest 5 pcs or 10 pcs for prototype circuit board assembly testing. Of course, one or two piece is also OK, so long as it can be verified.

There is no Minimum Order Quantity (MOQ) limit for PCB assembly -even one piece is accepted. Moreover, all components’ price is 100% based on your BOM list. If you need an equivalent replacement to reduce cost, we must get your official approval. Our team is qualified to manage the complete prototype PCB assembly process, which includes the sourcing of all components and their management, PCB assembly, quality control, function testing, and delivery.

Our small batch printed circuit board assembly is a specialized service that enables us to take complicated designs, prepare them for assembly, and test them without your needing to worry about PCB assembly workmanship. The prototype pcb manufacturing section of our manufacturing facility has a unique layout that allows for flexible use of both automated and manual parts-loading stations. Our staff is qualified and experienced in managing fine-pitch parts and ball grid arrays (BGAs) for high-density FR-4 PCBs. Our team is capable of manufacturing prototype pcb manufacturing volumes from 1 to 1000 PCBs.

What Low Volume PCB Assembly Services are Available?

Below are some of the low volume pcb assembly services available:

Surface Mount Technology (SMT) Assembly

SMT technology has to do with producing low-cost printed circuit boards. This technology functions by soldering the PCB components found on the surface. This is a modern way of mounting components. This doesn’t involve through holes drilling into the PCB.

This is included among the most efficient and affordable mode of mounting components. Asides from this, it is basic and simple, and only sees less or very few errors. This makes them great for low volume PCB assembly.

Through Hole Technology Assembly

This has to do with hole drilling through the printed circuit board. After the hole is drilled, the component will be mounted with legs through these holes. This will increase the bonding strength.

This method is also the most suitable when mounting straight components having high mechanical load. This includes switches and connectors. This technology should also be used to mount components, which would pass through mechanical and environmental stresses.

During prototyping, you will take very little time to mount and replace its components.

Leaded and Lead Free PCB Assembly

You may also choose leaded PCB assembly. This deals with using materials having lead products. This approach makes use of lead materials in the assembly of PCBs. You can as well choose lead-free PCB assembly that involves assembling PCBs with lead-free materials.

This approach of accepting PCBs at lower costs is an environmentally friendly one. You should also consider the use of low-cost lead-free PCB assembly. This is useful because it is less harmful to people’s health.

Multilayer, Double Sided, and Single Sided Multilayer PCB Assembly

Some PCB types, which can be assembled via low volume PCB assembly, are double-sided or single-sided pcbs among others.

Asides from this, you could also decide to assemble pcbs having multilayers. However, you should note that assembling multilayer PCBs will raise the cost of assembling printed circuit boards.

On this note, always avoid having too many PCB layers, if you have plans to lower the PCB assembly price.

Prototyping PCB Assembly Services

Immediately the design of your low volume PCB is ready, then you can make the prototype. This prototype will be used to give you a rough idea of the final look of your low volume PCB.

Asides from this, it will serve as the major blueprint, which will guide the whole process of manufacturing low-cost PCBs. Asides from this, the prototype also gives you a great visual impression of the design and then lets you make some important adjustments.

If you make some changes to your design, never forget to update the BOM.

Quick Turn PCB Assembly service

Also, you’ll be opportune to have low volume PCB assembly at very high speed. This deals with assembling PCBs at a much faster rate while ensuring that the low budget is maintained.

It makes use of high tech machinery that will select and place the components of the PCB on the PCB at an advanced speed. Although the speed used in assembling the PCB is quite high, you’ll discover that the quality of the PCB will remain very high.

How to Choose a Low Volume PCB Assembly Manufacturer?

The prototype PCB assembly is a complex process. It’s not even a part of the actual circuit board manufacturing process, still, it holds immense significance. This is due to their undeniable benefits. Here are some important benefits of our prototype PCB assembly.

This type of PCB assembly helps in analyzing the design and functionality of the circuit board before its final production. This saves several possible failures by identifying bugs in the early stages of the manufacturing process. This helps save on cost, productive time, as well as resources.

The feasibility of the circuit can be checked in the design stage. Hitech Circuits lays emphasis on using design for manufacturability or DFM which helps offer quick and accurate output.

A good small batch PCB vendor can help you get your design into production without undermining the quality and reliability of your circuit. Don’t forget to keep these things in mind when selecting a small PCB vendor for your next project:

1) Make sure that the vendor has a positive reputation

2) Check if they have a solid online presence, both locally and on the web.

3) Make sure that they offer quick turnaround times and clear communication with customers.

4) Be sure to ask for details about design and assembly options, including layers, design rules, and parts availability.

5) Check out what the turnaround time will be for your project. Again, they should have a variety of options for you to choose from.

6) Do a little research on the vendor’s quality control processes and use this information when making your decision.

This guide is here to help you make the right choice when selecting a PCB vendor for your project. If you’re ready to get started with your design, find out how easy it can be with Hitechpcba.com

Estimating the Cost of a Prototype PCB Assembly Project

The ability to accurately predict the cost of your prototype pcb production project can prove a tough ask. However, you can always come up with estimates of the total costs. So how can you go about this? One of the best ways often entails getting a quote from your prototype PCB assembly manufacturer. The requirements, however, prove different with each prototype PCB assembly company. For instance, at Hitech Circuits PCB and Assembly, you can always get a complete price quotation in 24 hours once you have sent your PCB design file complete with a bill of materials. Further, you will have to enclose specific details such as the BOM list, your Gerber file, and the required prototype PCB quantities. Additionally, you will also have to specify any need for special technology utilization in the assembly process.

At Hitechpcba PCB and Assembly, no MOQ limit exists for prototype printed circuit board assembly, and you can always order even a single piece of PCB prototype. What’s more, the price of components will be based on the BOM list you send. But you can always request the equivalent replacements to save the cost.

The company has the experience and capacity to handle your Low Volume PCB Assembly. And Hitech Circuits PCB manufacturing and pcb Assembly possesses the latest technologies and equipment to handle your Low Volume PCB Assembly needs ranging from one piece up to a thousand pieces. Hinging their operations on delivering quality PCB prototypes within short turn-around times, picking us will always prove an inspired decision.

Another crucial aspect of estimating the cost of production depends on the services and PCB product sourcing avenues of the prototype PCB service provider. For instance, if the company has a qualified team of engineers and sources the parts necessary for your PCB design assembly process in house, then the cost drastically reduces. The opposite also rings true for companies that outsource services or PCB components. Here the price will always rise, and this can hamper your plans with the developed low volume PCB projects.

Finding a PCB turnkey service provider for yourLow Volume PCB Assembly and sources for the diverse components allows you to worry yourself with the design, which saves you money. Additionally, a company such as Hitech Circuits that sources for components ensure that the components used in the assembly process of the PCB prototype are of top-rate quality owing to the quality certification and standards that it must protect in its operations. With advanced optimal selection criteria for packaging, you also get to reduce the cost, a crucial indicator of the total cost of the prototype smt pcb assembly.

Another crucial determinant of a Low Volume PCB Assembly service provider is labor charges, parts costs, and bare circuit board pricing or rates. To determine this, all you have to do entails accessing the company’s website, sending your prototype PCB Gerber file, and getting an estimate based on the supplier or assembly service provider.

Most Low Volume PCB Assembly providers guarantee prompt delivery though this often depends on the capacity of the company and the documentation you submit. For instance, the average timeline always comes at two weeks when all factors remain constant. However, for Hitech Circuits, you will only need three days to get your delivery. Consequently, the quality and turn-around delivery times have to figure in your cost estimates, especially based on your budget and application needs. It becomes crucial to note that we do a thorough evaluation of the engineering concerns and inquiries related to components before stating the PCB assembly process.

Reasons to Choose us to Build your Low Volume PCB Assembly

Hitech Circuits capability in low volume PCB assembly services includes the following:

We have multiple assembly lines to meet the most demanding of customer requirements.

We provide prototypes even for high density printed circuit board assemblies, as soon as the design is finalized. This helps the customers get an idea of how their PCBs look in the final stage.

We have fully automated surface mount lines to handle single, double sided SMD assembly.

We are experienced in working with a vast range of materials, and have excellent expertise in hand and wave soldering.

All Low Volume PCB Assembly undergoes rigorous quality checks and inspection before they are dispatched to the customers’ end.

We have a highly experienced quality team who stringently check the entire circuit board assembly to ensure the components are working as per the client’s requirements.

We Offer Complete Turnkey Small Batch Assembly Services

Unlike many of our competitors, we can handle every aspect of your project, including PCB component procurement, fabrication and assembly, and we can do it at a much lower cost than you will find anywhere in the United States or Europe without quality compromised. As a single-source PCB manufacturing entity, we can save you the time and hassle of having to locate and deal with multiple suppliers. Even better, there's no minimum order quantity required.

Add to that the difficulty of pinning down the person you need to talk to when there’s a problem anywhere in the process. It’s so much easier to have everything under one roof. That’s what you get when you partner with Hitech Circuits. We work with your design specifications, fabricate your prototypes, design your PCBs and finish your low-cost Low Volume PCB Assembly. No running around trying to pull it all together. You tell us what you need, and we make it for you fast, so you can concentrate on the actual business of putting together, marketing and selling your product.

0086-755-29970700

sales@hitechpcb.com; sales@hitechcircuits.com

2F, Building C, Suojia Technology Park, Hangcheng, Bao’an, Shenzhen, Guangdong, China 518126

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese