Ceramic PCB Fabrication

Add To Cart

Contact Us

Add To Cart

Contact Us

Description

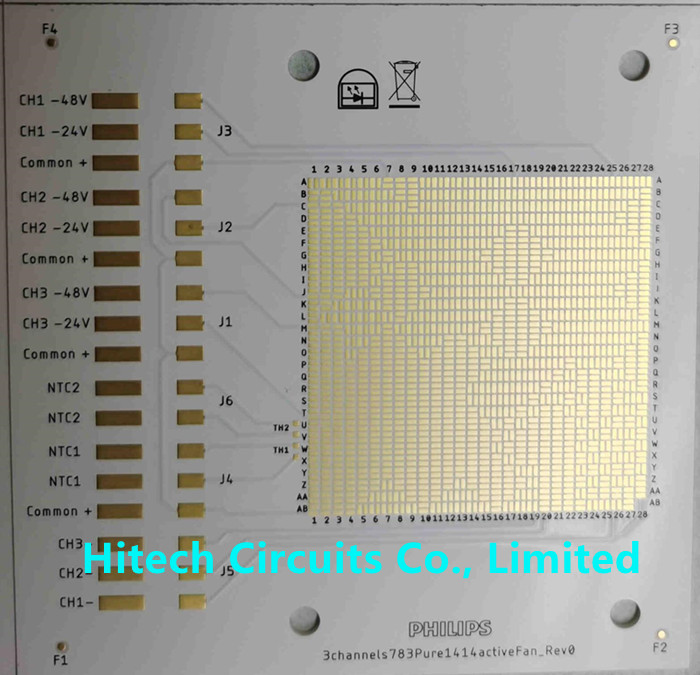

Ceramic PCB and Substrate: Alumina PCB, Aluminum Nitride Base, Copper Clad

Ceramic PCB (ceramic substrate) refers to a special process board in which a copper foil is directly bonded to a surface of an alumina (Al2O3 ) or aluminum nitride (AlN) ceramic substrate (single or double-sided or multilayer Ceramic PCB) at a high temperature. The ultra-thin composite substrate produced has excellent electrical insulation properties, high thermal conductivity, excellent solderability, and high adhesion strength, and can etch various patterns like a PCB board, and has a large current carrying current ability.

Hitech Circuits is a professional ceramic pcb manufacturer, supplier from

Ceramic PCB Parameter

Ceramic PCB in high pressure, high insulation, high frequency, high temperature, and high reliable and minor volume electronic products, then Ceramic PCB will be your best choice.

Why Ceramic PCB has such excellent performance?

96% or 98% Alumina (Al2O3), Aluminum Nitride (ALN), or Beryllium Oxide (BeO) PCB

Conductors material: For thin film technology, thick film technology, it’ll be silver palladium (AgPd), gold pllladium (AuPd); For DCB (Direct Copper Bonded) it’ll be copper only

Application temp: -55~850℃

Thermal conductivity value: 16W~28W/m-K (Al2O3); 150W~240W/m-K for ALN , 220~250W/m-K for BeO;

Max compression strength: >7,000 N/cm2

Breakdown Voltage (KV/mm): 15/20/28 for 0.25mm/0.63mm/1.0mm respectively

Thermal expansion conefficient(ppm/K): 7.4 (under 50~200℃)

Why Purchase Your Ceramic PCBs from HITECH CIRCUITS?

At HITECH CIRCUITS, we are dedicated to producing and selling quality PCBs to all of our customers. With over 15 years of experience in the electronic industry we are committed to producing custom ceramic PCBs that meet up with the various electronic devices at hand. Our professionals manufacture nothing but top-notch ceramic PCBs that are developed to tackle your demands. In addition, we assure that you will get nothing but the best and affordable prices for all the quality ceramic PCB we manufacture. Regardless of the quality of the printed circuit boards that you want, it will be gotten at a decent price.

Ceramic PCB Classification

1. According to the material Alumina (Al2O3) Ceramic PCB Beryllium Oxide (BeO) Ceramic PCB Aluminum Nitride (ALN) Ceramic PCB

2. According to the manufacturing process HTCC (High-Temperature Co-fired Ceramic) LTCC (Low-Temperature Co-fired Ceramic) DBC (Direct Bonded Copper) DPC (Direct Plate Copper) Ceramic PCB is a thermal conductive organic ceramic circuit board with high thermal conductivity and prepared at a temperature below 250°C using thermally conductive ceramic powder and organic adhesive, ceramic PCB types by material including alumina pcb, Aluminum nitride ceramic PCB, Copper clad ceramic PCB, Zirconia ceramic base PCB.

Four types: HTCC, LTCC, DBC, and DPC

1. The HTCC (high temperature co-fired) preparation method requires a temperature above 1300°C, but due to the choice of the electrode, the preparation cost is quite expensive.

2. The LTCC (low temperature co-firing) requires a calcination process of about 850°C, but circuit precision is poor, and the thermal conductivity is low.

3. The DBC requires formingan alloy between the copper foil and the ceramic, and the calcination temperature needs to be strictly controlled within the temperature range of 1065-1085°C. Because the DBC requires the thickness of the copper foil, generally, it cannot be less than 150-300 microns. Therefore, the wire width to depth ratio of such ceramic circuit boards is limited.

4. The preparation methods of DPC include vacuum coating, wet coating, exposure and development, etching, and other process links, so the price of its products is relatively high. In addition, in terms of shape processing, DPC 1800 ceramic fiber board plates need to be laser cut. Traditional drilling and milling machines and punching machines cannot accurately process them, so the bonding force and line width are more precise.

Hitech manufactures Ceramic PCB (printed circuit board) using the latest materials and technology, that has worked with thousands of electronic engineers to get their products into market, we have full technical knowledge and Ceramic PCB manufacturing experience in Ceramic PCB fabrication (also called Ceramic printed circuit board manufacturing or rigid Ceramic printed circuit board fabrication).

0086-755-29970700

sales@hitechpcb.com; sales@hitechcircuits.com

2F, Building C, Suojia Technology Park, Hangcheng, Bao’an, Shenzhen, Guangdong, China 518126

Chinese

Chinese English

English Russian

Russian Spanish

Spanish Portuguese

Portuguese